Your customers want to know that the products they buy from you are safe and reliable. They look for commitments to quality like the UL Recognition Mark.

NEWS YOU CAN USE: Pleasant Precision confirms its commitment to customers by earning UL Certification

Topics: injection molding, plastic, quality, certification, plastic molding'

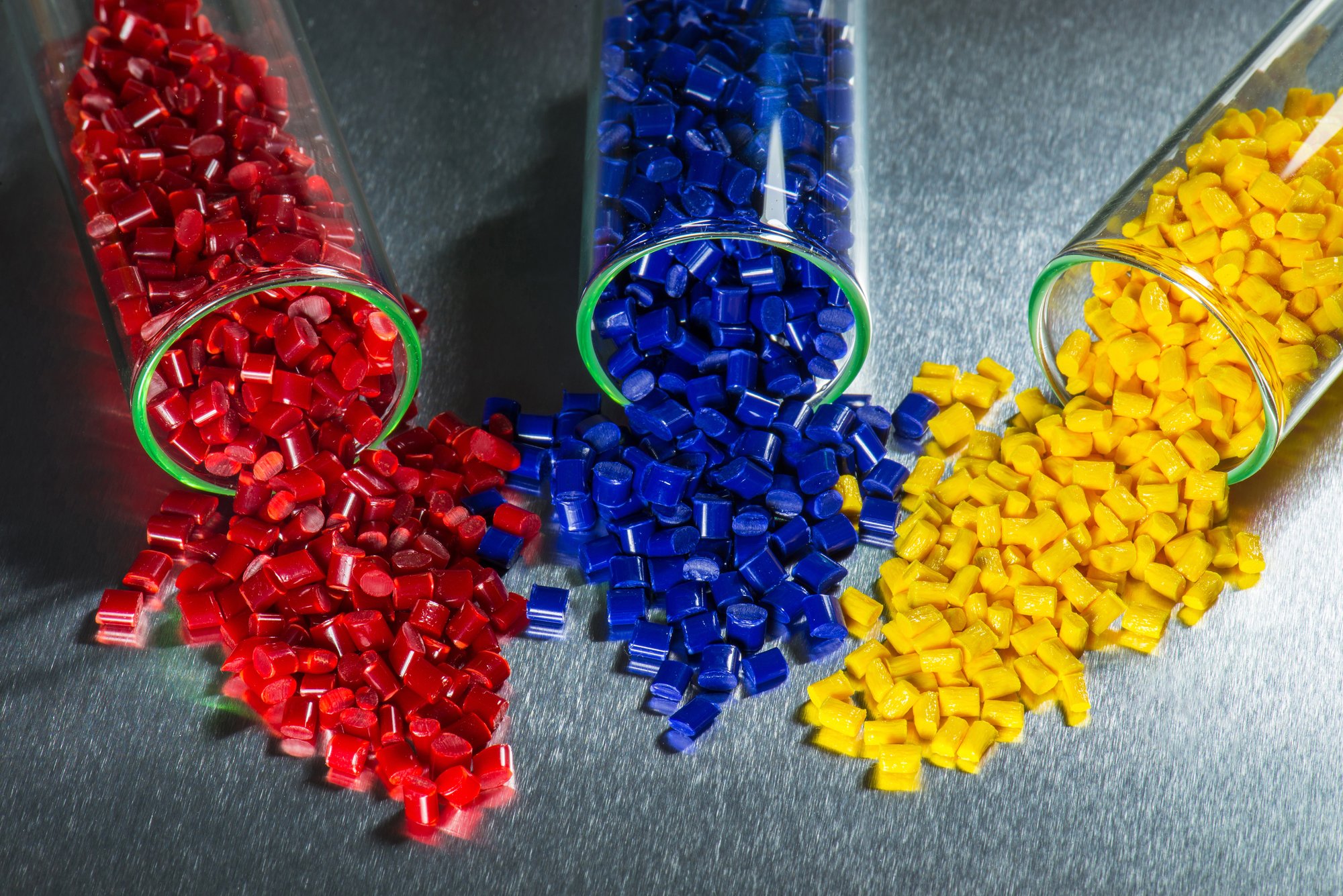

The Benefits of Consolidating Thermoplastic Resins in Plastic Injection Molding

How many thermoplastic resins does your company use?

If you are using a wide variety of resins, it may be time to review and consolidate. Using a large cross-section of resins can cost your company a lot of time and money. There are many benefits to consolidating thermoplastic resins for plastic injection molding, both for the customer as well as the manufacturer.

Topics: injection molding, plastic, plastic molding', lean manufacturing

Topics: plastic, quality, improvement, advanced manufacturing, processes

In today’s world everyone is always looking for the best deal they can find. Unfortunately everyone markets themselves as the solution to all your problems, and this leads to confusion when selecting a supplier. It’s not until it’s too late that you actually know whether or not you have chosen the right path. I’m here to tell you that in the Plastic Injection Molding world there is a way to get the most bang for your buck EVERY TIME, and that is Round Mate.

Topics: injection molding, plastic, improvement, processes, round mate

Due to the current market conditions and increasing demand, the Nylon 66 supply is expected to be tight for several years to come. You can expect an increase in price anywhere from $.10-$.50/lb depending on the grade.

Topics: Mold Components, injection molding, plastic, plastic molding', advanced manufacturing

Topics: plastic, advanced manufacturing, CULTURE

How vertical toolmaking adds flexibility and extends mold life

In 1976, Ron Pleasant founded Pleasant Precision, Inc. with his wife, Carol, to produce tooling for the plastic industry. Now located in a 54,000 sq. ft. building in Kenton, OH, Team PPI produces tooling for a wide number of industries that use injection molded components, including consumer products, medical, automotive, appliance, and electrical and electronics industries. Ron Pleasant invented the Round Mate System of tooling in 1989, and developed System II tooling as an advance on Round Mate technology in 1997.

Topics: injection molding, plastic, quality, certification, systems, lean manufacturing, advanced manufacturing, processes, methods

The NPE 2018 “The Plastics Show” took place in Orlando last week, and featured professionals in the plastics industry from 128 countries, and in every field from automotive, to construction, to medical. As members of the plastic and injection molding industry, PPI found that the conference was a key event that could benefit their future success.

Topics: plastic, improvement, systems, advanced manufacturing, processes, future

NPE 2018 The Plastics Show begins May 7, 2018, and provides access to the people and companies that are influencing the future of the plastics industry. Professionals from 128 countries are gathering to provide a glimpse into the future of plastics. The show features professionals in the fields of appliances, automotive industry, construction, medical devices, packaging, and more.

Topics: Insider, plastic, improvement, systems, plastic molding', lean manufacturing, advanced manufacturing, processes, methods, future

Technology advances every day, whether it’s in giant strides or baby steps. Advanced manufacturing is how industry leaders find a nexus between the present and the future of technology. Using technology to improve products and processes is a system of advancement like any other. When used in manufacturing, it will make processes more efficient, and further improve the quality of products.

Topics: injection molding, plastic, quality, improvement, systems, plastic molding', lean manufacturing, advanced manufacturing, NASA

.png)