In 1976, Ron Pleasant founded Pleasant Precision, Inc. with his wife, Carol, to produce tooling for the plastic industry. Now located in a 54,000 sq. ft. building in Kenton, OH, Team PPI produces tooling for a wide number of industries that use injection molded components, including consumer products, medical, automotive, appliance, and electrical and electronics industries. Ron Pleasant invented the Round Mate System of tooling in 1989, and developed System II tooling as an advance on Round Mate technology in 1997.

Ron Pleasant

Recent Posts

How vertical toolmaking adds flexibility and extends mold life

Topics: injection molding, plastic, quality, certification, systems, lean manufacturing, advanced manufacturing, processes, methods

When it comes to plastic, times have certainly changed. While 40 years ago anything made with plastic was considered cheap. Today there are thousands of plastic products, including things like computer housings, automobile parts, and medical parts.

Topics: Mold Components

Moisture affects the quality of the molded part in different ways, and the extent is determined by either the specific resin being processed or the purpose of the part. Improper or incomplete drying can create problems, either when the part is being processed or when the product is in use, or sometimes, both.

Topics: injection molding

The objective of injection molding is to produce identical moldings at the specified quality each and every time. Repeatability is the key: setup, process, inspection, repeat.

Topics: injection molding

We recently wrote about the differences between Nylon 6 and Nylon 6,6. Now we want to discuss the differences between Nylon 4,6, Nylon 11, and Nylon 12 and differentiating them from Nylon 6 and Nylon 6,6.

Topics: Mold Components

Nylons are semi-crystalline resins with a very low viscosity at melting point, excellent chemical resistance, good temperature resistance, and good toughness (moisture). There are 8 types of nylons: Nylon 6; Nylon 6,6; Nylon 4,6; Nylon 6,9; Nylon 6,10; Nylon 6,12; Nylon 11; and Nylon 12.

Topics: Mold Components

Plastic, coming from the Greek “plastikos” meaning “capable of being shaped and molded”: we use it multiple times daily, but what do you know about it? You may be surprised to learn just how advanced plastic is; for example, a fleece jacket can be made from 25 recycled plastic drink bottles. Did you know there are two families of plastics? Thermoplastics and thermosets make up the two families. There are several characteristics of each that differentiate the two. Thermoplastics soften when heated and harden when cooled, can be re-softened and reformed repeatedly, and have a limited upper service temperature. Thermosets harden when heated, cannot be re-softened or reprocessed, and have a high upper service temperature.

Topics: Mold Components

Are you in search of an injection molding company but stuck on where you should start looking? Once you choose a company to work with, you are likely to stay with them for all your future needs as well so it is important to find a reputable, trustworthy company. Here are some questions you should ask before you choose the company to work with.

Topics: injection molding

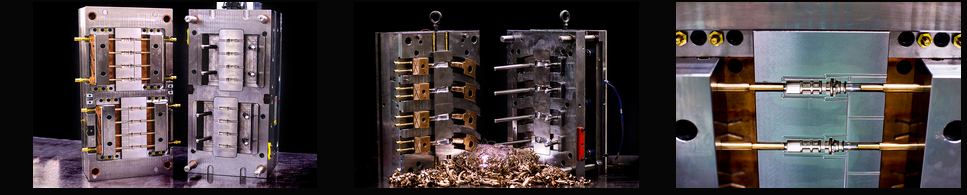

When discussing a plastic injection mold, what exactly are we describing? Simply put, a plastic injection mold is a tool, custom designed using Computer Aided Design (CAD, in engineering) or Computer Aided Machining (CAM, in manufacturing utilizing CNC machining tools) to produce a specific plastic part. Using thermoplastics, these molds can produce anything from helmet visors to pipes to bottles to parts for cars and many, many other everyday items one can imagine.

Topics: injection molding