Contract manufacturing in injection molding is the process of outsourcing the production of plastic parts or components to a manufacturer who specializes in injection molding.

This process starts at the design phase and ends with an assembled, ready-to-ship product. Full-service contractors offer tool-making and can offer design support in the early stages of the process.

Read More

Topics:

injection molding,

systems,

plastic molding'

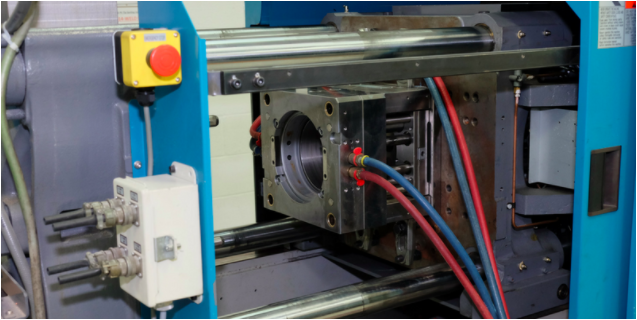

On a surface level, injection molding might seem like a simple process. The idea of it is. The process itself is a little more complex. Within the actual process of injection molding, there is a intricate system of efficiency and cost-effectiveness.

Read More

Topics:

Mold Components,

injection molding,

quality,

systems,

plastic molding',

lean manufacturing,

advanced manufacturing,

processes,

methods,

round mate

In 1976, Ron Pleasant founded Pleasant Precision, Inc. with his wife, Carol, to produce tooling for the plastic industry. Now located in a 54,000 sq. ft. building in Kenton, OH, Team PPI produces tooling for a wide number of industries that use injection molded components, including consumer products, medical, automotive, appliance, and electrical and electronics industries. Ron Pleasant invented the Round Mate System of tooling in 1989, and developed System II tooling as an advance on Round Mate technology in 1997.

Read More

Topics:

injection molding,

plastic,

quality,

certification,

systems,

lean manufacturing,

advanced manufacturing,

processes,

methods

The NPE 2018 “The Plastics Show” took place in Orlando last week, and featured professionals in the plastics industry from 128 countries, and in every field from automotive, to construction, to medical. As members of the plastic and injection molding industry, PPI found that the conference was a key event that could benefit their future success.

Read More

Topics:

plastic,

improvement,

systems,

advanced manufacturing,

processes,

future

NPE 2018 The Plastics Show begins May 7, 2018, and provides access to the people and companies that are influencing the future of the plastics industry. Professionals from 128 countries are gathering to provide a glimpse into the future of plastics. The show features professionals in the fields of appliances, automotive industry, construction, medical devices, packaging, and more.

Read More

Topics:

Insider,

plastic,

improvement,

systems,

plastic molding',

lean manufacturing,

advanced manufacturing,

processes,

methods,

future

Technology advances every day, whether it’s in giant strides or baby steps. Advanced manufacturing is how industry leaders find a nexus between the present and the future of technology. Using technology to improve products and processes is a system of advancement like any other. When used in manufacturing, it will make processes more efficient, and further improve the quality of products.

Read More

Topics:

injection molding,

plastic,

quality,

improvement,

systems,

plastic molding',

lean manufacturing,

advanced manufacturing,

NASA

At Pleasant Precision, we know that continuous improvement and development is necessary for being a successful manufacturer. For continuous improvements to be made, every employee has to be on board. It’s not just random bursts of improvement efforts, it’s a mindset for what you and your company do every day. Sometimes it sounds like a good idea on paper, but getting each and every employee on board can be a struggle.

Read More

Topics:

injection molding,

plastic,

quality,

improvement,

certification,

systems,

plastic molding'

.png)