Back in July 2018, President Trump implemented a 25% tariff on China-made plastic injection molds. Unexpectedly in December, the Trump Administration lifted the tariff for at least one year - a decision many say is likely to hurt American mold makers but help U.S. plastics companies that supply automakers. Below we share some insight on the tariff suspension, what it means for mold makers, and what it ultimately means for you.

Topics: Mold Components, injection molding, advanced manufacturing, tariffs

Due to the current market conditions and increasing demand, the Nylon 66 supply is expected to be tight for several years to come. You can expect an increase in price anywhere from $.10-$.50/lb depending on the grade.

Topics: Mold Components, injection molding, plastic, plastic molding', advanced manufacturing

The Advantages of Injection Molding with Round Mate® Systems

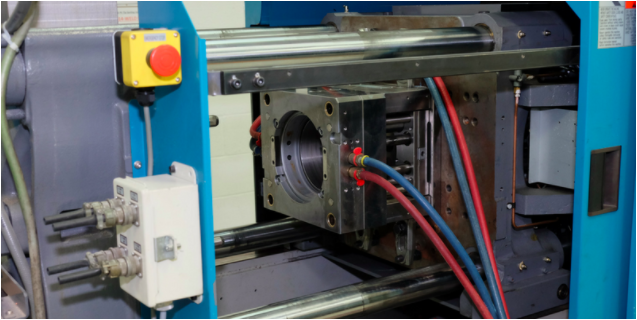

On a surface level, injection molding might seem like a simple process. The idea of it is. The process itself is a little more complex. Within the actual process of injection molding, there is a intricate system of efficiency and cost-effectiveness.

Topics: Mold Components, injection molding, quality, systems, plastic molding', lean manufacturing, advanced manufacturing, processes, methods, round mate

When it comes to plastic, times have certainly changed. While 40 years ago anything made with plastic was considered cheap. Today there are thousands of plastic products, including things like computer housings, automobile parts, and medical parts.

Topics: Mold Components

We recently wrote about the differences between Nylon 6 and Nylon 6,6. Now we want to discuss the differences between Nylon 4,6, Nylon 11, and Nylon 12 and differentiating them from Nylon 6 and Nylon 6,6.

Topics: Mold Components

Nylons are semi-crystalline resins with a very low viscosity at melting point, excellent chemical resistance, good temperature resistance, and good toughness (moisture). There are 8 types of nylons: Nylon 6; Nylon 6,6; Nylon 4,6; Nylon 6,9; Nylon 6,10; Nylon 6,12; Nylon 11; and Nylon 12.

Topics: Mold Components

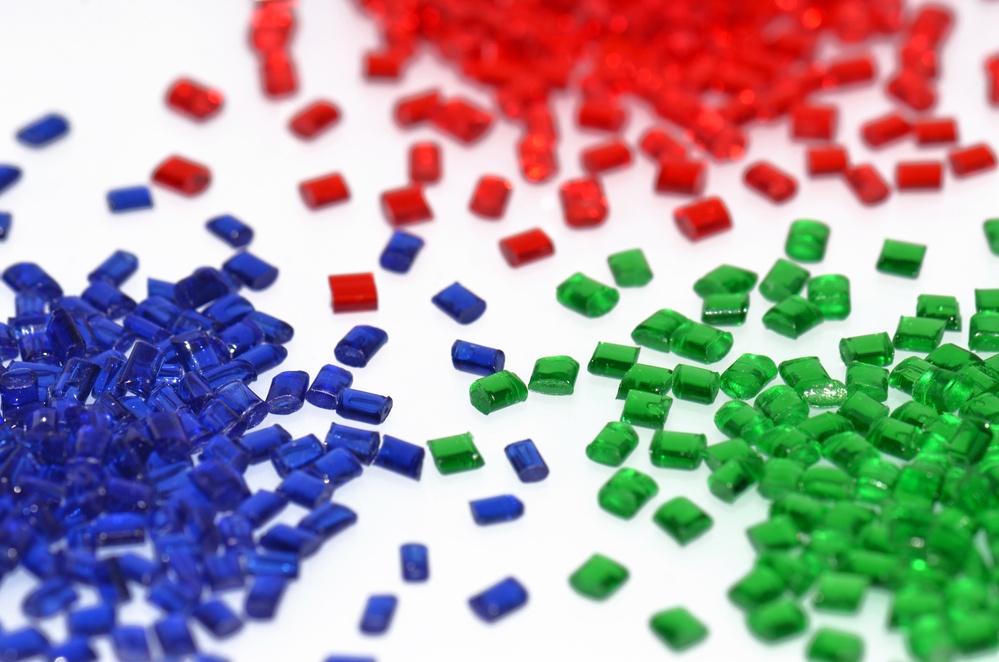

Plastic, coming from the Greek “plastikos” meaning “capable of being shaped and molded”: we use it multiple times daily, but what do you know about it? You may be surprised to learn just how advanced plastic is; for example, a fleece jacket can be made from 25 recycled plastic drink bottles. Did you know there are two families of plastics? Thermoplastics and thermosets make up the two families. There are several characteristics of each that differentiate the two. Thermoplastics soften when heated and harden when cooled, can be re-softened and reformed repeatedly, and have a limited upper service temperature. Thermosets harden when heated, cannot be re-softened or reprocessed, and have a high upper service temperature.

Topics: Mold Components

If you’re looking for a balance of strength, transparency, and economy you may want to consider Styrolux for your next modeling project.

Styrolux is a Styrene-Butadiene Block Copolymer (SBC) with several different polymer blends that each have added benefits and disadvantages depending on what you need to model. Types of Stryrolux include: General Purpose Polystyrene (GPPS), Styrene-Methylmeth Acrylate (SMMA), High Impact Polystyrene (HIPS), Stryrene-Acrylonitrite (SAN), and Polypropylene (PP).

Topics: Mold Components

Mold cooling has advanced and become more efficient throughout the years. Before there was newer technology to create optimized circulation throughout mold plates and cavities, there were mold cooling systems to circulate water through base plates not necessarily within the cavities.

Topics: Mold Components

Anything made out of plastic used to be considered cheap; however, today, thousands of products are produced from plastics. Some of these products include automobile parts, computer housings, and medical parts. The first synthetic plastic was produced in 1869 from plant material cellulose by John Wesley Hyatt. His synthetic plastic was used in eyeglass frames, combs, billiard balls, shirt collars, dentures, buttons and photographic film.

Topics: Mold Components