Contract manufacturing in injection molding is the process of outsourcing the production of plastic parts or components to a manufacturer who specializes in injection molding.

This process starts at the design phase and ends with an assembled, ready-to-ship product. Full-service contractors offer tool-making and can offer design support in the early stages of the process.

Read More

Topics:

injection molding,

systems,

plastic molding'

Your customers want to know that the products they buy from you are safe and reliable. They look for commitments to quality like the UL Recognition Mark.

Read More

Topics:

injection molding,

plastic,

quality,

certification,

plastic molding'

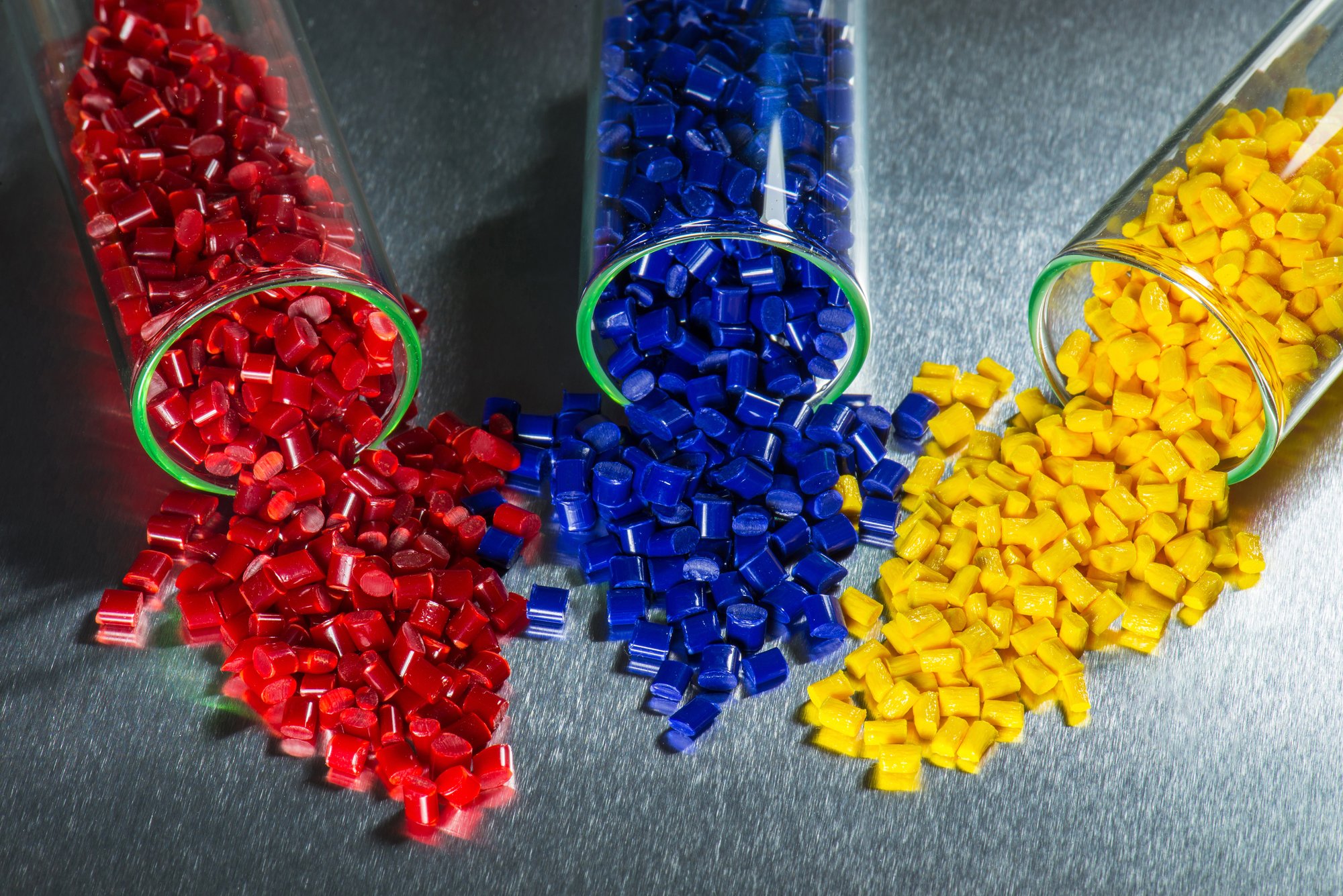

How many thermoplastic resins does your company use?

If you are using a wide variety of resins, it may be time to review and consolidate. Using a large cross-section of resins can cost your company a lot of time and money. There are many benefits to consolidating thermoplastic resins for plastic injection molding, both for the customer as well as the manufacturer.

Read More

Topics:

injection molding,

plastic,

plastic molding',

lean manufacturing

Due to the current market conditions and increasing demand, the Nylon 66 supply is expected to be tight for several years to come. You can expect an increase in price anywhere from $.10-$.50/lb depending on the grade.

Read More

Topics:

Mold Components,

injection molding,

plastic,

plastic molding',

advanced manufacturing

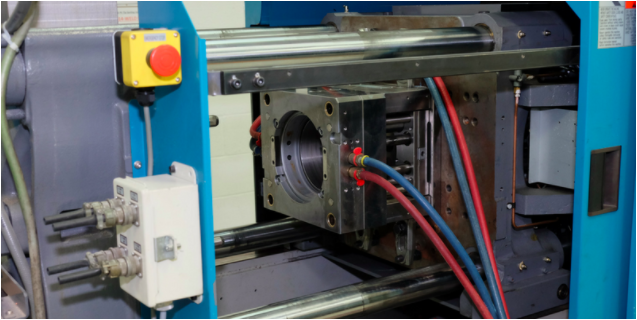

On a surface level, injection molding might seem like a simple process. The idea of it is. The process itself is a little more complex. Within the actual process of injection molding, there is a intricate system of efficiency and cost-effectiveness.

Read More

Topics:

Mold Components,

injection molding,

quality,

systems,

plastic molding',

lean manufacturing,

advanced manufacturing,

processes,

methods,

round mate

NPE 2018 The Plastics Show begins May 7, 2018, and provides access to the people and companies that are influencing the future of the plastics industry. Professionals from 128 countries are gathering to provide a glimpse into the future of plastics. The show features professionals in the fields of appliances, automotive industry, construction, medical devices, packaging, and more.

Read More

Topics:

Insider,

plastic,

improvement,

systems,

plastic molding',

lean manufacturing,

advanced manufacturing,

processes,

methods,

future

Technology advances every day, whether it’s in giant strides or baby steps. Advanced manufacturing is how industry leaders find a nexus between the present and the future of technology. Using technology to improve products and processes is a system of advancement like any other. When used in manufacturing, it will make processes more efficient, and further improve the quality of products.

Read More

Topics:

injection molding,

plastic,

quality,

improvement,

systems,

plastic molding',

lean manufacturing,

advanced manufacturing,

NASA

At Pleasant Precision, we know that continuous improvement and development is necessary for being a successful manufacturer. For continuous improvements to be made, every employee has to be on board. It’s not just random bursts of improvement efforts, it’s a mindset for what you and your company do every day. Sometimes it sounds like a good idea on paper, but getting each and every employee on board can be a struggle.

Read More

Topics:

injection molding,

plastic,

quality,

improvement,

certification,

systems,

plastic molding'