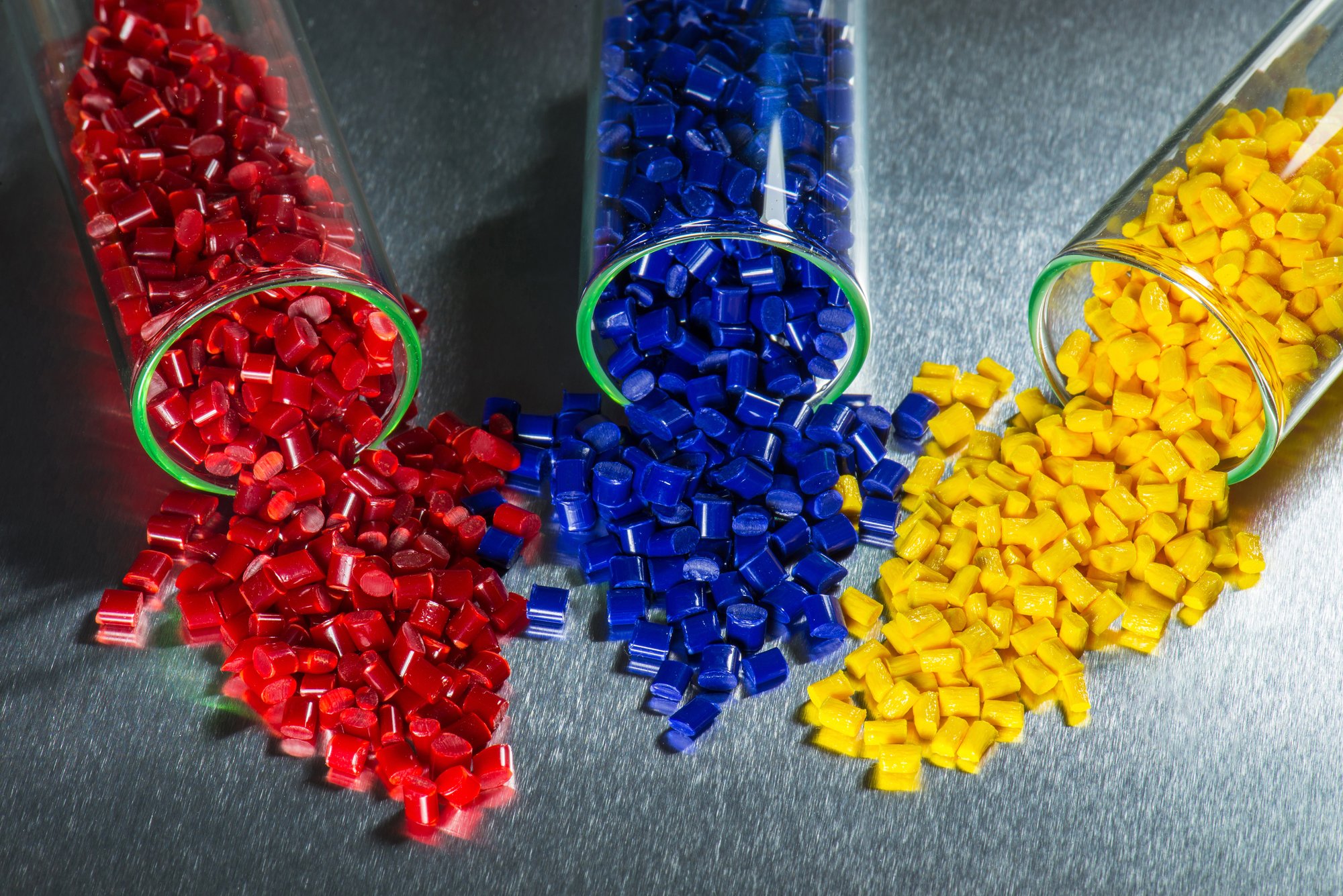

How many thermoplastic resins does your company use?

If you are using a wide variety of resins, it may be time to review and consolidate. Using a large cross-section of resins can cost your company a lot of time and money. There are many benefits to consolidating thermoplastic resins for plastic injection molding, both for the customer as well as the manufacturer.

.png)