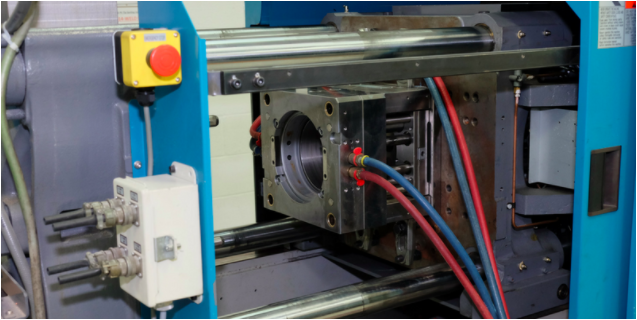

Contract manufacturing in injection molding is the process of outsourcing the production of plastic parts or components to a manufacturer who specializes in injection molding.

This process starts at the design phase and ends with an assembled, ready-to-ship product. Full-service contractors offer tool-making and can offer design support in the early stages of the process.

Read More

Topics:

injection molding,

systems,

plastic molding'

Captain Billy Tyne faces the fight of his life. Miles from shore, he and his crew battle a monster storm. Waves 40 feet high pound the fishing boat, washing up on deck to sweep men and equipment overboard. Shrieking winds drown out all communication. All hands work feverishly, but the storm wins. The Andrea Gail and her entire crew are lost – sunk into the depths of the Atlantic Ocean.

Read More

Topics:

injection molding,

processes,

future,

tariffs

Your customers want to know that the products they buy from you are safe and reliable. They look for commitments to quality like the UL Recognition Mark.

Read More

Topics:

injection molding,

plastic,

quality,

certification,

plastic molding'

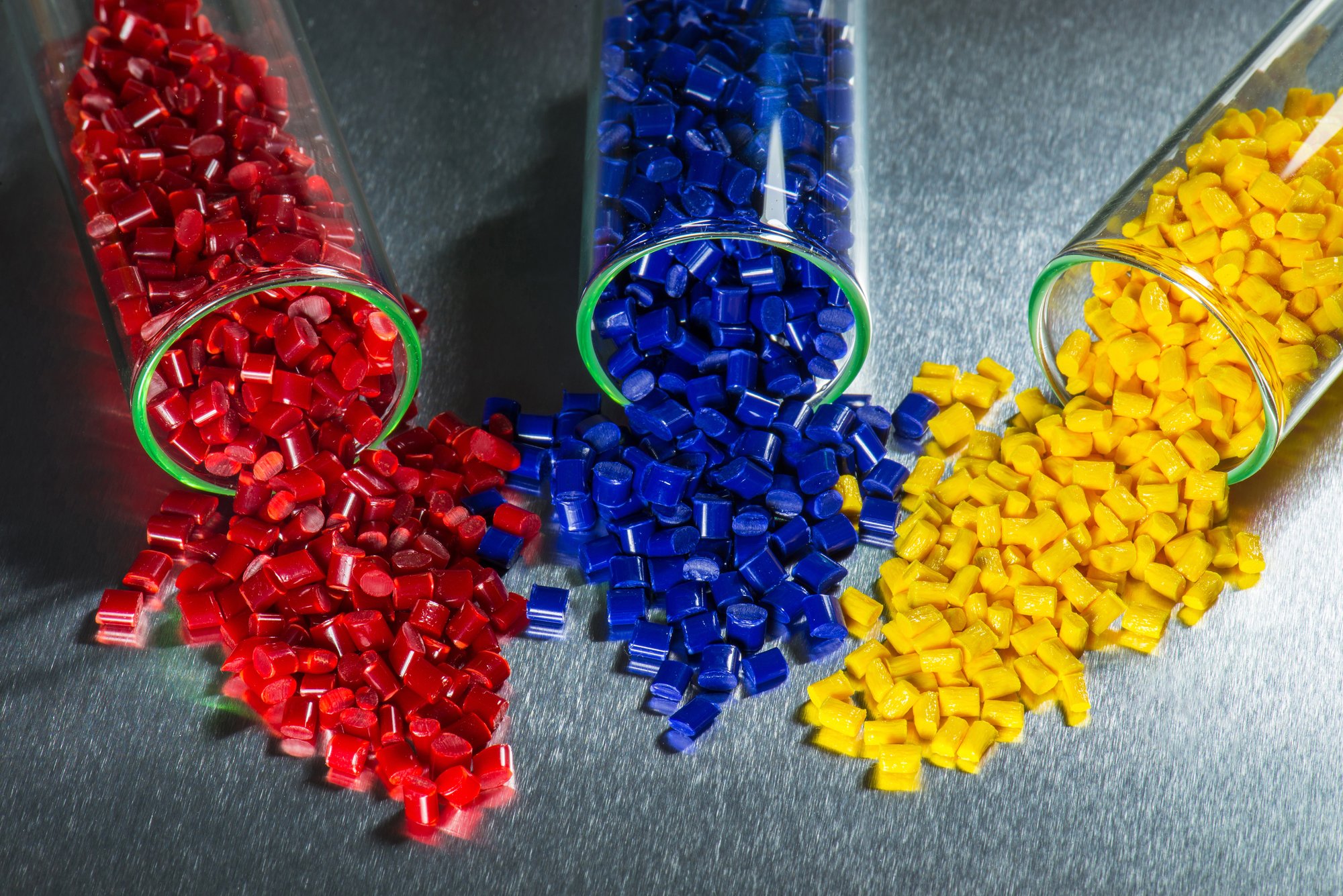

How many thermoplastic resins does your company use?

If you are using a wide variety of resins, it may be time to review and consolidate. Using a large cross-section of resins can cost your company a lot of time and money. There are many benefits to consolidating thermoplastic resins for plastic injection molding, both for the customer as well as the manufacturer.

Read More

Topics:

injection molding,

plastic,

plastic molding',

lean manufacturing

In today’s world everyone is always looking for the best deal they can find. Unfortunately everyone markets themselves as the solution to all your problems, and this leads to confusion when selecting a supplier. It’s not until it’s too late that you actually know whether or not you have chosen the right path. I’m here to tell you that in the Plastic Injection Molding world there is a way to get the most bang for your buck EVERY TIME, and that is Round Mate.

Read More

Topics:

injection molding,

plastic,

improvement,

processes,

round mate

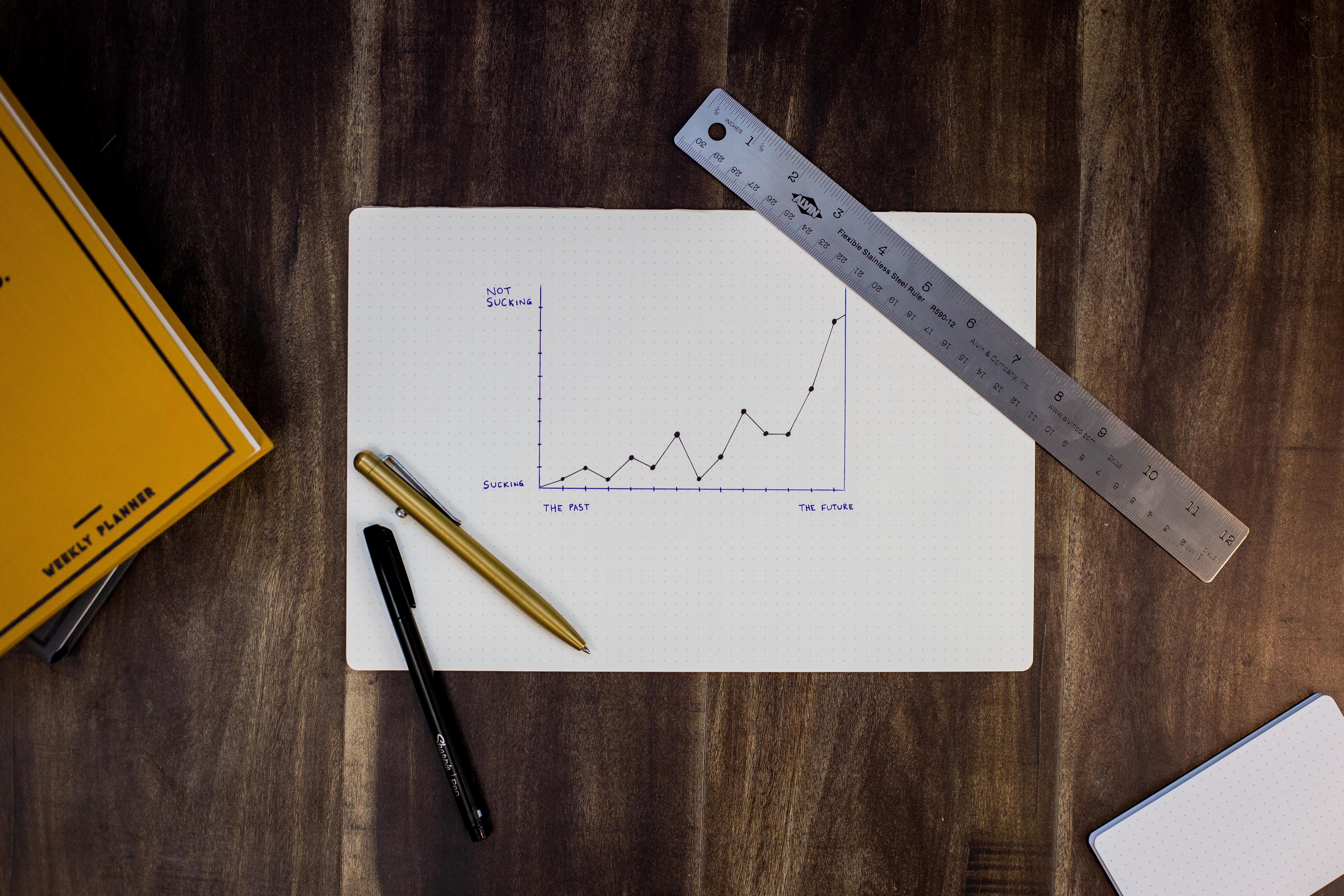

Back in July 2018, President Trump implemented a 25% tariff on China-made plastic injection molds. Unexpectedly in December, the Trump Administration lifted the tariff for at least one year - a decision many say is likely to hurt American mold makers but help U.S. plastics companies that supply automakers. Below we share some insight on the tariff suspension, what it means for mold makers, and what it ultimately means for you.

Read More

Topics:

Mold Components,

injection molding,

advanced manufacturing,

tariffs

Due to the current market conditions and increasing demand, the Nylon 66 supply is expected to be tight for several years to come. You can expect an increase in price anywhere from $.10-$.50/lb depending on the grade.

Read More

Topics:

Mold Components,

injection molding,

plastic,

plastic molding',

advanced manufacturing

Earlier this year, President Trump implemented a 35% tariff on plastic injection molds

Read More

Topics:

injection molding,

lean manufacturing,

advanced manufacturing,

round mate,

tariffs

On a surface level, injection molding might seem like a simple process. The idea of it is. The process itself is a little more complex. Within the actual process of injection molding, there is a intricate system of efficiency and cost-effectiveness.

Read More

Topics:

Mold Components,

injection molding,

quality,

systems,

plastic molding',

lean manufacturing,

advanced manufacturing,

processes,

methods,

round mate

In 1976, Ron Pleasant founded Pleasant Precision, Inc. with his wife, Carol, to produce tooling for the plastic industry. Now located in a 54,000 sq. ft. building in Kenton, OH, Team PPI produces tooling for a wide number of industries that use injection molded components, including consumer products, medical, automotive, appliance, and electrical and electronics industries. Ron Pleasant invented the Round Mate System of tooling in 1989, and developed System II tooling as an advance on Round Mate technology in 1997.

Read More

Topics:

injection molding,

plastic,

quality,

certification,

systems,

lean manufacturing,

advanced manufacturing,

processes,

methods