Technology advances every day, whether it’s in giant strides or baby steps. Advanced manufacturing is how industry leaders find a nexus between the present and the future of technology. Using technology to improve products and processes is a system of advancement like any other. When used in manufacturing, it will make processes more efficient, and further improve the quality of products.

Topics: injection molding, plastic, quality, improvement, systems, plastic molding', lean manufacturing, advanced manufacturing, NASA

At Pleasant Precision, we know that continuous improvement and development is necessary for being a successful manufacturer. For continuous improvements to be made, every employee has to be on board. It’s not just random bursts of improvement efforts, it’s a mindset for what you and your company do every day. Sometimes it sounds like a good idea on paper, but getting each and every employee on board can be a struggle.

Topics: injection molding, plastic, quality, improvement, certification, systems, plastic molding'

Moisture affects the quality of the molded part in different ways, and the extent is determined by either the specific resin being processed or the purpose of the part. Improper or incomplete drying can create problems, either when the part is being processed or when the product is in use, or sometimes, both.

Topics: injection molding

The objective of injection molding is to produce identical moldings at the specified quality each and every time. Repeatability is the key: setup, process, inspection, repeat.

Topics: injection molding

Injection molding is the processing method used in 75% of the plastics industry. It is used to convert raw plastic to useful shapes for all types of industries including the automobile industry. Although there is a substantial upfront investment, injection molding is beneficial because the cost is low after the initial investment.

Topics: injection molding

When you are preparing to inject molding you need to establish process parameters based on information about the mold capabilities. This will mean you will process from a plastics-point-of-view, verifying and then proving over time, and optimizing setup times with mold modifications.

This is a called a systematic process optimization, with single or multiple cavities, used by cold runner or hot runner molds. It can be used by amorphous or semi-crystalline thermoplastic materials. All of these decisions are made using data.

Topics: injection molding

Are you in search of an injection molding company but stuck on where you should start looking? Once you choose a company to work with, you are likely to stay with them for all your future needs as well so it is important to find a reputable, trustworthy company. Here are some questions you should ask before you choose the company to work with.

Topics: injection molding

Injection molding can be a complex industry to understand. However, some of the processes and terminology don’t necessarily have to be to those unfamiliar to what it is and how it’s done.

Here’s a quick glossary of some of the most commonly used terms in our industry to help you become more familiar with what we do and how we do it.

Topics: injection molding

Injection molding requires a highly skilled team of associates who specialize in pre- and post-production quality systems. For molds to be high quality and 100-percent effective, it’s crucial the injection molds are made under the highest possible tolerances in the plastics industry.

Topics: injection molding

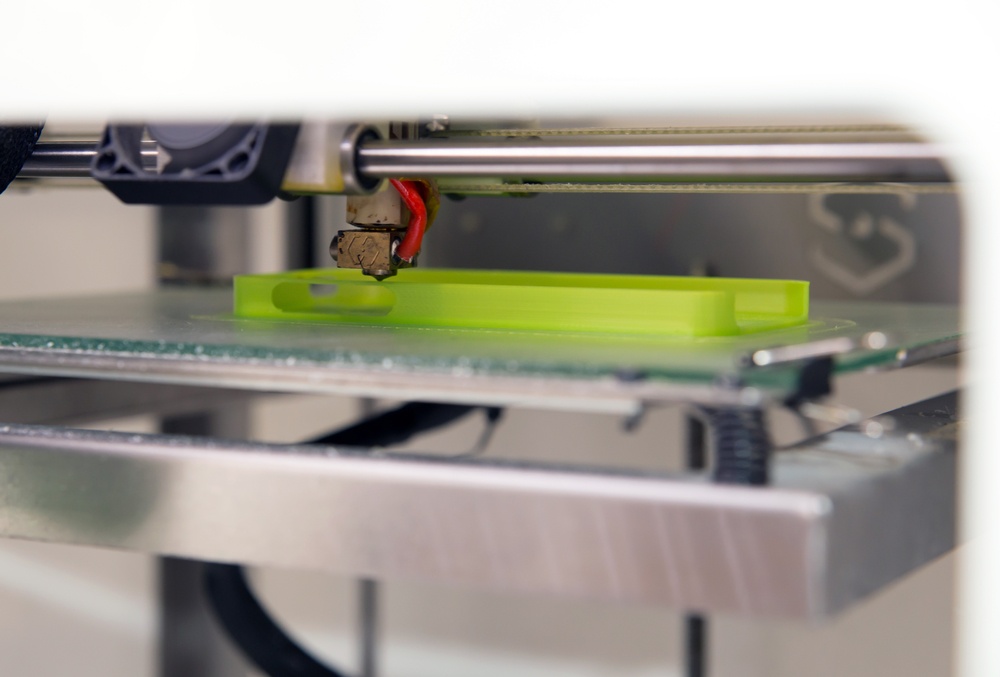

3D Printing sounds complex, but it’s actually pretty simple once you get the hang of it. And when it comes to the world of injection molding, this new technology is turning out to have a pretty huge impact.

Essentially, instead of printing pages of paper with black ink or colored ink, as an inkjet printer will do, a 3D printer takes a digital file and creates a 3D solid object. This is also known as additive manufacturing. You may be wondering how this works and why it is so important. Here are 6 facts about 3D printing.

Topics: injection molding