When it comes to plastic, times have certainly changed. While 40 years ago anything made with plastic was considered cheap. Today there are thousands of plastic products, including things like computer housings, automobile parts, and medical parts.

Moisture affects the quality of the molded part in different ways, and the extent is determined by either the specific resin being processed or the purpose of the part. Improper or incomplete drying can create problems, either when the part is being processed or when the product is in use, or sometimes, both.

Topics: injection molding

The objective of injection molding is to produce identical moldings at the specified quality each and every time. Repeatability is the key: setup, process, inspection, repeat.

Topics: injection molding

We recently wrote about the differences between Nylon 6 and Nylon 6,6. Now we want to discuss the differences between Nylon 4,6, Nylon 11, and Nylon 12 and differentiating them from Nylon 6 and Nylon 6,6.

Topics: Mold Components

Nylons are semi-crystalline resins with a very low viscosity at melting point, excellent chemical resistance, good temperature resistance, and good toughness (moisture). There are 8 types of nylons: Nylon 6; Nylon 6,6; Nylon 4,6; Nylon 6,9; Nylon 6,10; Nylon 6,12; Nylon 11; and Nylon 12.

Topics: Mold Components

Injection molding is the processing method used in 75% of the plastics industry. It is used to convert raw plastic to useful shapes for all types of industries including the automobile industry. Although there is a substantial upfront investment, injection molding is beneficial because the cost is low after the initial investment.

Topics: injection molding

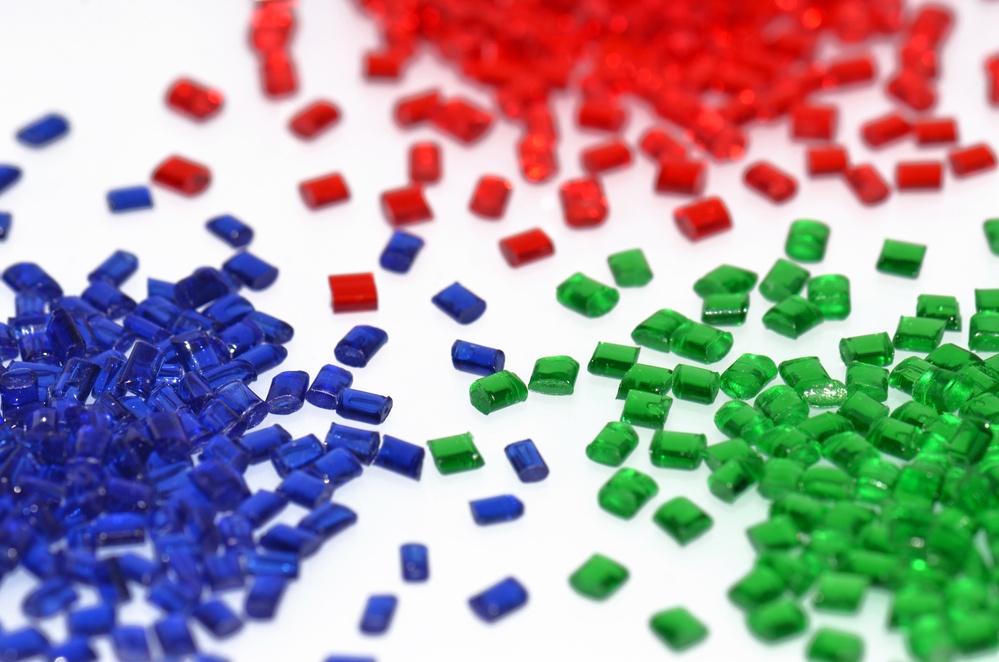

Plastic, coming from the Greek “plastikos” meaning “capable of being shaped and molded”: we use it multiple times daily, but what do you know about it? You may be surprised to learn just how advanced plastic is; for example, a fleece jacket can be made from 25 recycled plastic drink bottles. Did you know there are two families of plastics? Thermoplastics and thermosets make up the two families. There are several characteristics of each that differentiate the two. Thermoplastics soften when heated and harden when cooled, can be re-softened and reformed repeatedly, and have a limited upper service temperature. Thermosets harden when heated, cannot be re-softened or reprocessed, and have a high upper service temperature.

Topics: Mold Components

When you are preparing to inject molding you need to establish process parameters based on information about the mold capabilities. This will mean you will process from a plastics-point-of-view, verifying and then proving over time, and optimizing setup times with mold modifications.

This is a called a systematic process optimization, with single or multiple cavities, used by cold runner or hot runner molds. It can be used by amorphous or semi-crystalline thermoplastic materials. All of these decisions are made using data.

Topics: injection molding

If you’re looking for a balance of strength, transparency, and economy you may want to consider Styrolux for your next modeling project.

Styrolux is a Styrene-Butadiene Block Copolymer (SBC) with several different polymer blends that each have added benefits and disadvantages depending on what you need to model. Types of Stryrolux include: General Purpose Polystyrene (GPPS), Styrene-Methylmeth Acrylate (SMMA), High Impact Polystyrene (HIPS), Stryrene-Acrylonitrite (SAN), and Polypropylene (PP).

Topics: Mold Components

Mold cooling has advanced and become more efficient throughout the years. Before there was newer technology to create optimized circulation throughout mold plates and cavities, there were mold cooling systems to circulate water through base plates not necessarily within the cavities.

Topics: Mold Components