Anything made out of plastic used to be considered cheap; however, today, thousands of products are produced from plastics. Some of these products include automobile parts, computer housings, and medical parts. The first synthetic plastic was produced in 1869 from plant material cellulose by John Wesley Hyatt. His synthetic plastic was used in eyeglass frames, combs, billiard balls, shirt collars, dentures, buttons and photographic film.

Are you in search of an injection molding company but stuck on where you should start looking? Once you choose a company to work with, you are likely to stay with them for all your future needs as well so it is important to find a reputable, trustworthy company. Here are some questions you should ask before you choose the company to work with.

Topics: injection molding

Injection molding can be a complex industry to understand. However, some of the processes and terminology don’t necessarily have to be to those unfamiliar to what it is and how it’s done.

Here’s a quick glossary of some of the most commonly used terms in our industry to help you become more familiar with what we do and how we do it.

Topics: injection molding

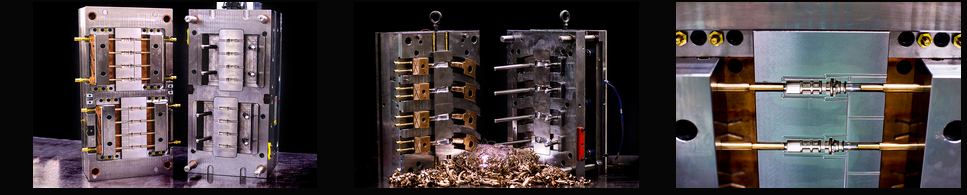

Injection molding requires a highly skilled team of associates who specialize in pre- and post-production quality systems. For molds to be high quality and 100-percent effective, it’s crucial the injection molds are made under the highest possible tolerances in the plastics industry.

Topics: injection molding

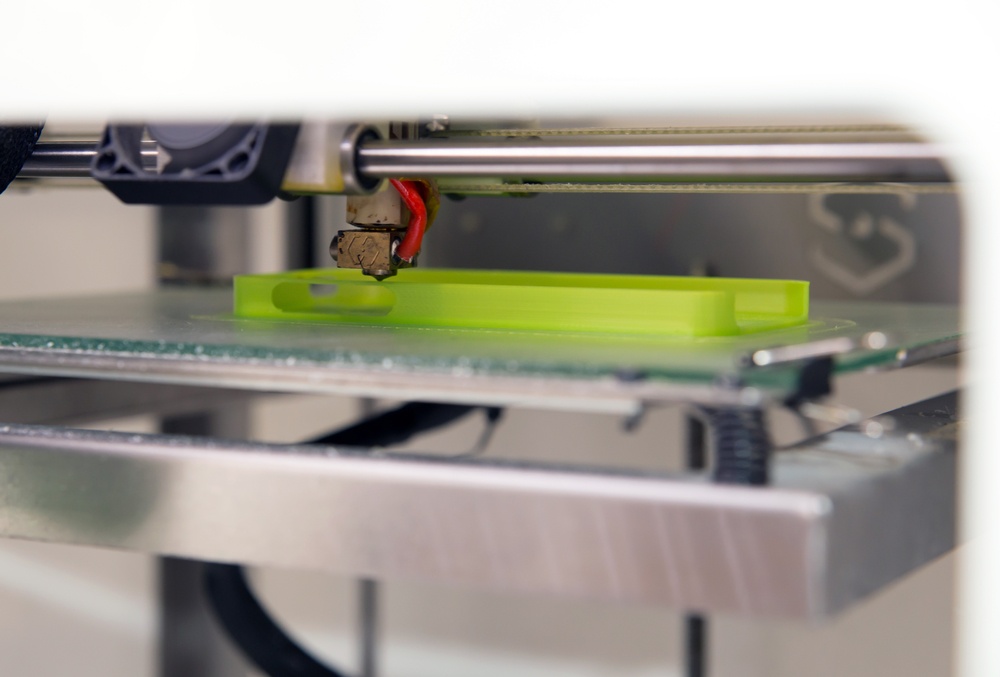

3D Printing sounds complex, but it’s actually pretty simple once you get the hang of it. And when it comes to the world of injection molding, this new technology is turning out to have a pretty huge impact.

Essentially, instead of printing pages of paper with black ink or colored ink, as an inkjet printer will do, a 3D printer takes a digital file and creates a 3D solid object. This is also known as additive manufacturing. You may be wondering how this works and why it is so important. Here are 6 facts about 3D printing.

Topics: injection molding

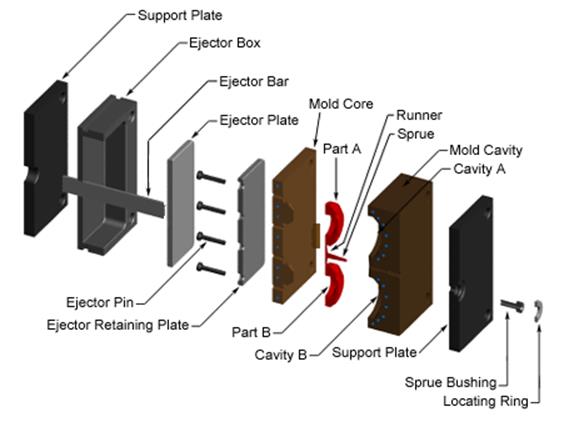

When discussing a plastic injection mold, what exactly are we describing? Simply put, a plastic injection mold is a tool, custom designed using Computer Aided Design (CAD, in engineering) or Computer Aided Machining (CAM, in manufacturing utilizing CNC machining tools) to produce a specific plastic part. Using thermoplastics, these molds can produce anything from helmet visors to pipes to bottles to parts for cars and many, many other everyday items one can imagine.

Topics: injection molding

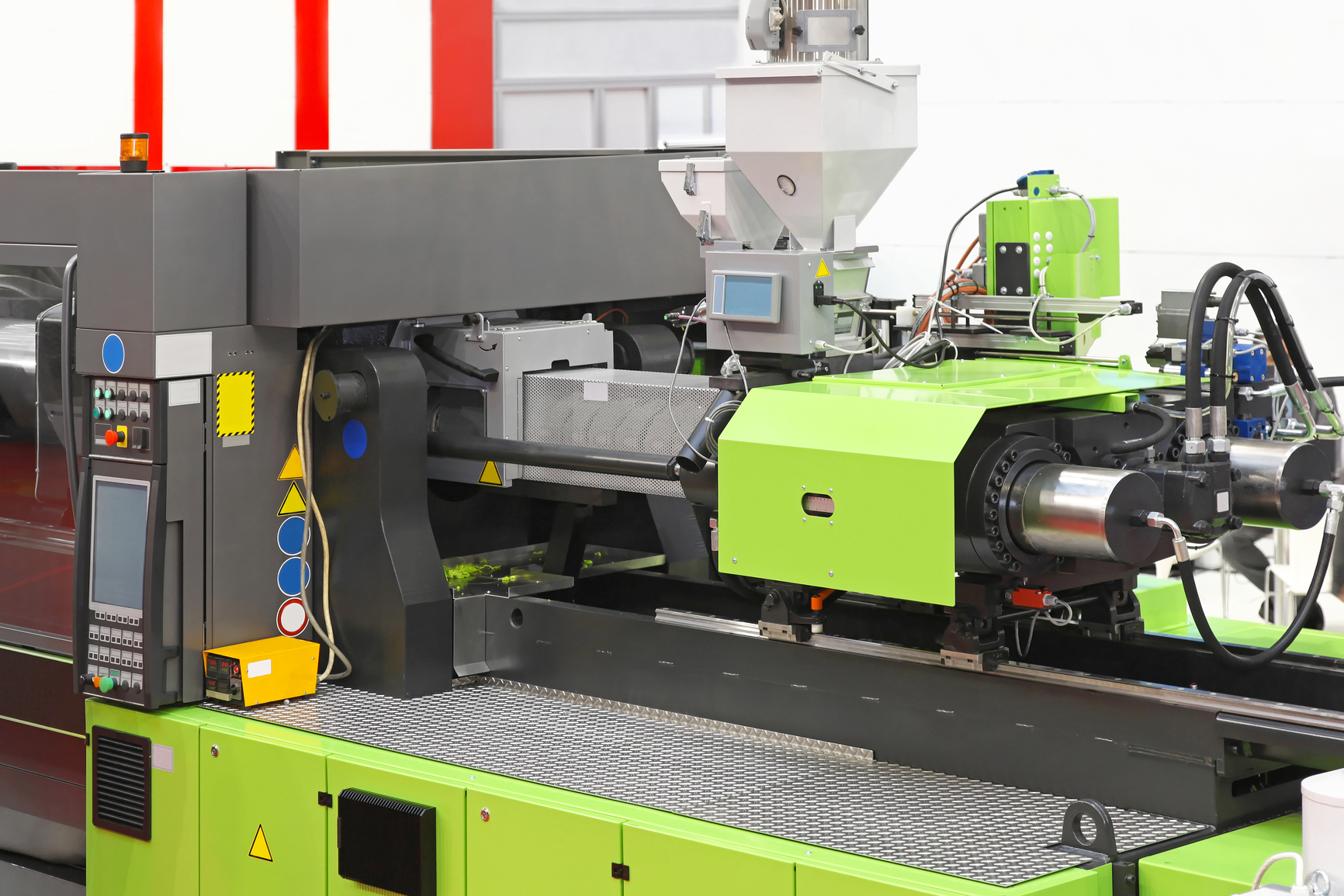

The plastic injection molding industry has a long history that dates back to the 19th century in Europe and America. Throughout the decades, many chemists and inventors have used a wide variety of plastic materials in the process.

However, the types of presses and machines used in the injection molding process have boiled down to two: Hydraulic and Electric with a Hybrid machine available.

Topics: injection molding

Different types of thermoplastic resins and their applications

Molds are used to make a variety of objects you use every day. And the materials used in replicating these objects come in a wide variety and are selected for each purpose based on flexibility, firmness, durability, and other key properties.

Topics: Mold Components

If you’re unsure what injection molding is exactly, we’re here to help begin your education on the subject.

Topics: injection molding

Understanding everything that goes into making precise, high quality injection molding can be confusing and complicated to those not familiar with everything that goes into one mold.

It’s not even all that easy to find clear, understandable information out there if you’re not sure where to start.

Topics: Mold Components