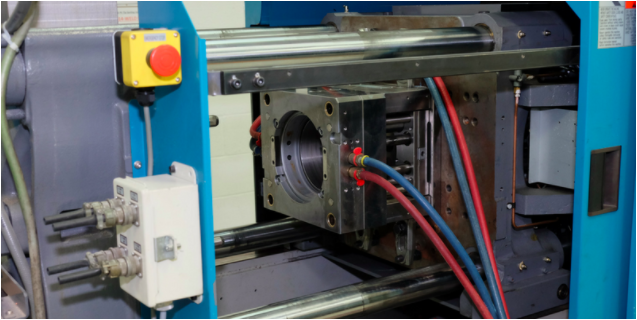

In today’s world everyone is always looking for the best deal they can find. Unfortunately everyone markets themselves as the solution to all your problems, and this leads to confusion when selecting a supplier. It’s not until it’s too late that you actually know whether or not you have chosen the right path. I’m here to tell you that in the Plastic Injection Molding world there is a way to get the most bang for your buck EVERY TIME, and that is Round Mate.

Topics: injection molding, plastic, improvement, processes, round mate

Pleasant Precision kicks off EOS - Entrepreneurial Operating System

Topics: lean manufacturing, CULTURE, eos

Back in July 2018, President Trump implemented a 25% tariff on China-made plastic injection molds. Unexpectedly in December, the Trump Administration lifted the tariff for at least one year - a decision many say is likely to hurt American mold makers but help U.S. plastics companies that supply automakers. Below we share some insight on the tariff suspension, what it means for mold makers, and what it ultimately means for you.

Topics: Mold Components, injection molding, advanced manufacturing, tariffs

Due to the current market conditions and increasing demand, the Nylon 66 supply is expected to be tight for several years to come. You can expect an increase in price anywhere from $.10-$.50/lb depending on the grade.

Topics: Mold Components, injection molding, plastic, plastic molding', advanced manufacturing

Topics: plastic, advanced manufacturing, CULTURE

Topics: injection molding, lean manufacturing, advanced manufacturing, round mate, tariffs

The difference between 3D printing and additive manufacturing

3D printing is a big deal when it comes to today’s technology. The concept alone is enough to wow people, and it’s starting to trickle into several different industries, even in the future making of artificial organs - where it’s called “bioprinting”.

Topics: quality, advanced manufacturing, processes, methods, future

The Advantages of Injection Molding with Round Mate® Systems

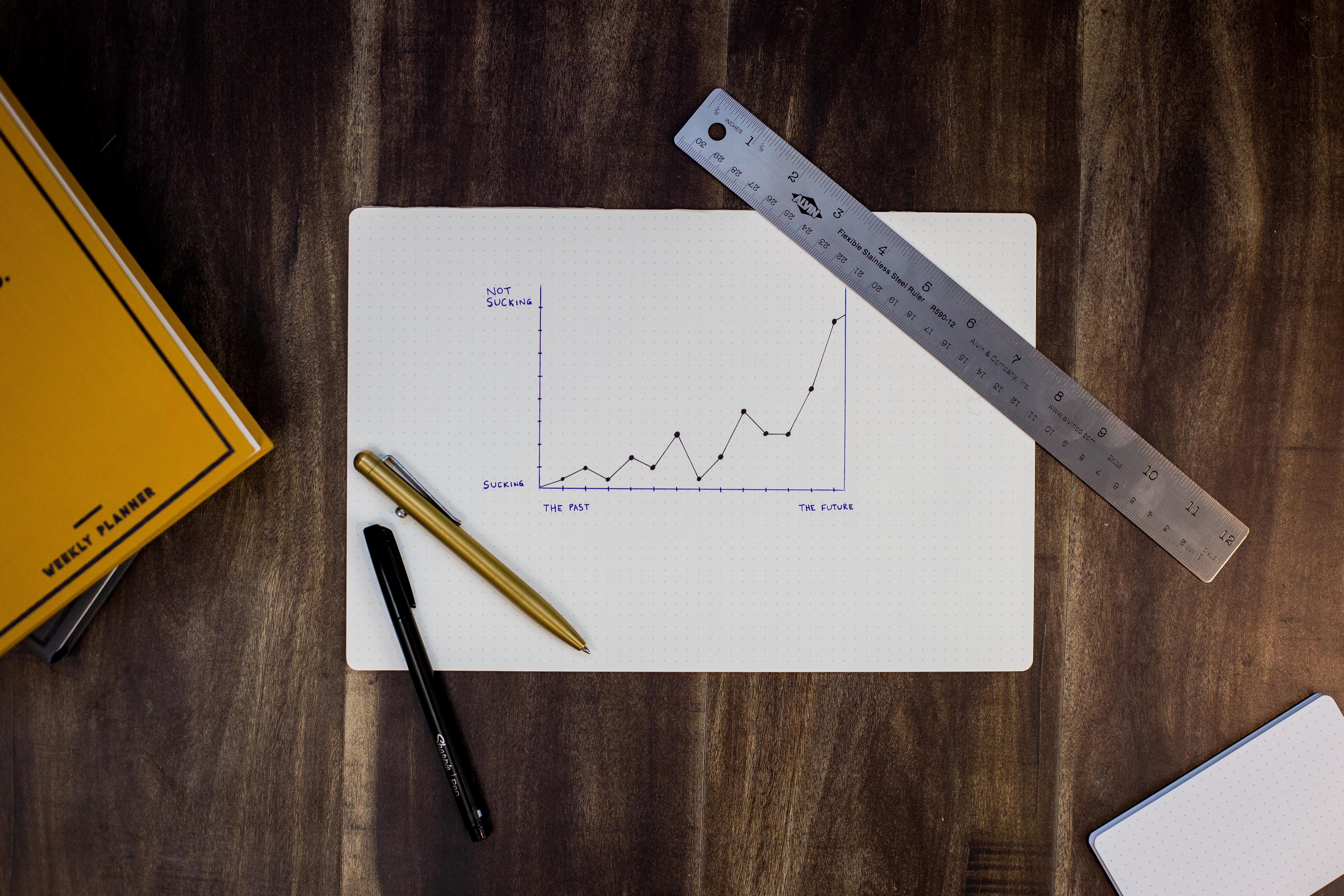

On a surface level, injection molding might seem like a simple process. The idea of it is. The process itself is a little more complex. Within the actual process of injection molding, there is a intricate system of efficiency and cost-effectiveness.

Topics: Mold Components, injection molding, quality, systems, plastic molding', lean manufacturing, advanced manufacturing, processes, methods, round mate

How vertical toolmaking adds flexibility and extends mold life

In 1976, Ron Pleasant founded Pleasant Precision, Inc. with his wife, Carol, to produce tooling for the plastic industry. Now located in a 54,000 sq. ft. building in Kenton, OH, Team PPI produces tooling for a wide number of industries that use injection molded components, including consumer products, medical, automotive, appliance, and electrical and electronics industries. Ron Pleasant invented the Round Mate System of tooling in 1989, and developed System II tooling as an advance on Round Mate technology in 1997.

Topics: injection molding, plastic, quality, certification, systems, lean manufacturing, advanced manufacturing, processes, methods

The NPE 2018 “The Plastics Show” took place in Orlando last week, and featured professionals in the plastics industry from 128 countries, and in every field from automotive, to construction, to medical. As members of the plastic and injection molding industry, PPI found that the conference was a key event that could benefit their future success.

Topics: plastic, improvement, systems, advanced manufacturing, processes, future

.png)

.png)