Understanding everything that goes into making precise, high quality injection molding can be confusing and complicated to those not familiar with everything that goes into one mold.

It’s not even all that easy to find clear, understandable information out there if you’re not sure where to start.

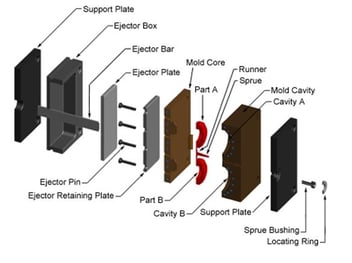

So we’re here to give you a hand in comprehending the basic components of a mold structure by looking at and defining the different parts.

Take a look at this thorough breakdown:

Support plate: The support plate is the foundation of the mold, it supports the mold and all the components within the mold.

Ejector Box: The ejector box houses the ejectors pins, blades, and mechanical lifters.

Ejector plate/ejector retaining plate: The ejector plate pushes the eject pins forward to eject the parts from the cavity or core. The ejector retaining plate holds the pins tight to the ejector plate returning it to position.

Ejector pin: In contact with the part and helps to push the part out of the cavity or core.

Part A, Part B: There is an A half and a B half to every mold. The A half usually has the cavity, which is where the part is formed.

The B half is where the core is and where the part is usually ejected from. The part will always shrink to the core or the B half so that part will stick to the core or B half when the mold opens so it can be ejected.

Sprue Bushing: The Sprue bushing is where the material is injected through the mold from the nozzle to fill the part within the cavity/core.

Leader pins: Leader pins are in all four corners of the mold. These align the two halves of the mold.

Locating Ring: The Locating Ring “locates” the mold to the center of the platen, which is is part of the injection molding machine itself and is used to mount the mold.

A clear understanding of the parts of injection molds is a great first step in knowing what we do and how our team of skilled associates delivers precise, quality equipment to our customers.

PPI Injection Molding is a team of highly skilled individuals who specialize in pre-production and production quality systems, focused on performing the tightest tolerances in the plastics industry.

For any questions you might have, be sure to call us toll free at (800) 860-3974 or email to info@teamppi.com.

Are you looking for ways to do more with less?

Download our Guide: Modular Molds Contribute to Lean Manufacturing Success- Shorten Time to Production

- Decrease Costs

- Compress Mold Change-over Times