When building plastic parts, consistency is key. Variables need to be recognized, so that a quality product is created, every time. A good part is made up of four things: the part design itself, the mold design, the material, and how it’s processed.

Variables in manufacturing can create pieces that are not uniform or are lesser quality. Manufacturing variables include chemistry, molecular weight, and additives within the resin, machine variables, such as design, room temperature, and wear, and, of course, operating variables like control settings and the operator.

Finished Part Characteristics include:

- Weight

- Strength

- Size

- Dimensional Stability

- Surface Finish

Your goal is to eliminate the effect of operating variables on these characteristics so that each piece and batch is uniform.

There are four plastic process variables that can determine whether or not pieces are uniform. These are:

- Plastic temperature

- Plastic flow rate (viscosity)

- Plastic pressure

- Plastic cooling rate and time

Temperature

Typically about 80 percent of the energy to melt the pellets comes from shear and 20 percent from the heater bands. It’s always important to process with the melt temperature at the manufacturer's mid-range. Measure and record the actual melt temperature using a pre-heated pyrometer.

Plastic Temperature is affected by:

- Barrel set points

- Screw design

- Screw recovery time

A nonuniform melt can have many consequences. Pieces can perform poorly, there could be marbling, color variances from part to part or other cosmetic blemishes. There could also be unexplained weak sections, short shots, or even unmelted particles.

Flow rate (viscosity)

Simply put, the faster you inject, the easier the polymer flows. As the plastic begins to flow, molecular segments and chains align in the direction of the flow. The viscosity decreases as the molecules become untangled, taking up less space and ‘slide’ by each other.

As the flow rate increases, the viscosity decreases!

The fill time begins from the start of injection to when the ram reaches the cutoff position. The fill time is not the time set on the first stage timer, so don’t confuse the two.

When operating the machine, make sure the molding is done on the flat portion of the viscosity curve. How do you Control Injection Velocity?

Plastic pressure

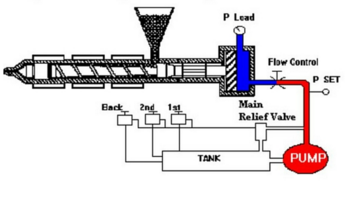

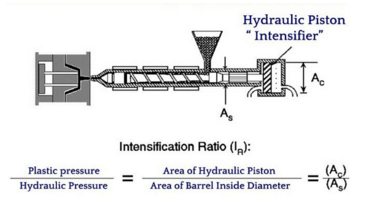

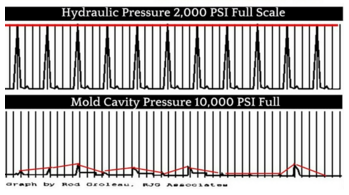

The pressure plastic is under also plays a part in how uniform pieces are. See illustrations below:

Plastic cooling rate and time

When plastic is cooling, the timing and rate are affected by the amount of heat energy that is in the plastic mold, the cavity surface temperature and mold heat transfer characteristics, the energy transfer capacity of the coolant, or the stiffness of the material. Additionally, thermal properties of the material, draft angles, and ejection configurations, can affect cooling rate and time.

Proper cooling must have a turbulent flow of coolant in the mold. The turbulent flow equals the Reynolds number > 5000. For rapid and uniform cooling, improve economics, and reduce cycle time. Make sure differential shrinkage is reduced, and minimize and internal stresses.

Mold temperature

It important to have direct cooling to areas the of highest need. These are:

- The cores

- Inside the corners

- And, the thick wall sections.

Measure the mold temperature by using a pre-heated surface pyrometer. Make sure to measure individual cavities, and draw a “mold temperature map.”

To ensure each piece is uniform and performs according to expectation, it’s important to optimize for these four plastic variables. Mold from the plastics point of view, using scientific techniques. Make sure to measure and record plastic conditions, and adjust when necessary, to match the part mean to the process mean.

Repeat these optimized plastic conditions, shot after shot, day in, day out, and run to run!