At Pleasant Precision we pride ourselves on being a “Solutions Provider” for our customers. We recently had the opportunity to complete a complete turnkey project for an OEM. This project included 6 injection molds, a custom-made interchangeable frame to house these molds, and a custom built rotary table to fit a Boy XS Molding Machine. The program also included the set-up of the molding processes and a quality validation for each part. When we delivered the equipment to the customer, it was fully qualified and ready to run production.

During the planning stages of this job we realized that we could develop a “standard” frame for this injection molding machine and therefore make all of our future tools within this system much easier to manufacture. This was something that was pivotal, not only for our ease of manufacturing, but for the bottom line of our customer since we were able to cut out engineering and manufacturing time.

It is important to understand exactly what kind of situation we were dealing with. The end product that the customer wanted was actually an over-mold of 5 other components. Since there would be extensive hand loading required from the operator, it was important that this tool was manufactured as a shuttle mold. A shuttle mold is simply a common mold but with 2 b halves. This allows the operator to load the inserts into one of the b halves while the other set is being molded.

Now this is where things get fun. Since we knew that the tool had to be a shuttle mold our customer had the vision of a full operator not only loading the hand loaded inserts but they also would be the operator of the shuttle sequence. The operator would pull out a b half when the cycle was done and then push the other back into the cycle. Then the operator would remove the parts, load the hand loads and repeat. It was at this moment that we knew we had to do something to further help our customer.

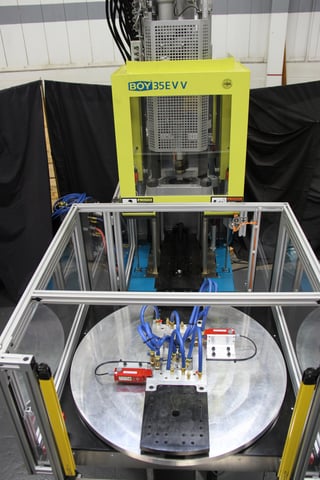

Many long hours and lots of grey hairs later, Pleasant Precision figured it out. We would fully design and manufacture a custom rotary table that would be able to adapt to this injection molding machine. This idea came to fruition not by a single person but by a collaboration of all the great minds we have here at PPI. Designing a fully functional rotary table with a fully function cooling system, a top notch safety system, and impeccable sequencing programming is not something a normal injection molder would do for its customer but then again that’s why we do not consider ourselves common injection molders. We are a true Solutions Provider to all of the plastics industry.

When this project was all finished our customer was happier than they could have ever imagined. We turned a simple turnkey project into something way beyond what they were expecting. We not only saved them money up front with tool cost but they will continue to save money as long as they run these parts thanks to the automatic rotary table and the elimination of the manual process. In essence, Pleasant Precision not only was able to produce what our customers expected but we supplied them with something far greater and their gratitude towards us meant just as much to us as anything else. The ability for our customer to be totally hands off and then have something run perfectly when it arrives in their facility is something that any customer would be happy to have and we were more than happy to provide it.